| Author | Message | ||

leo |

Would appreciate any info regarding Oliver 1855 dsl. How well do they hold up? What is their value range? | ||

Chris Losey (Admin) |

The 1855 has to be the most notorious Oliver made. For some reason, Oliver thought they could put a turbo on an engine without doing something to cool the oil. Add to this some crank shafts that weren't properly balanced, 2 piece wrist pin bushings that failed, and that adds up to many engines that failed, all in the name of the almighty dollar. Despite all of this, there are still alot of them out there earning their keep. A neighbor of mine has an 1855 that he uses to plant all of his crops, and he is doing his secondary tillage and planting in one pass, so he is putting the tractor to work. Another neighbor has an 1855 FWA that they use mostly for chore jobs, but when they had to put a new clutch in their 2-135 during spring plowing, the 1855 took it's place until the 2-135 was back up and running. Basically, if you keep the oil changed every 50 hours and keep the engine cool, they are a pretty reliable unit. If rebuilt properly, they can be a very productive unit. The transmission for the 1855 is very stout, as are almost all Oliver transmissions. It always amazes me that when I go to an auction, the other brands of tractors will have listed, motor was overhauled x years ago, transmission x number of years ago. The Olivers usually just say when the motor was rebuilt, because you don't have to do tranny work that often. Add to that closed center hydraulics, and you have a very handy tractor, big enough to do some serious field work, yet small and nimble enough to get around the farm with ease. The 1855s I see for sale have been in the $5,000 to $7,000 range for good 2wd ones. Add about $1500 to that for front wheel assist. That fact that their value is still that high tells you something about them. If they were truly useless, they would sell for 2 or 3 thousand as glorified lawn mowers. I remember Dad telling about how the 1885s that they sold were the first tractors that sold for more than $10,000 from our dealership. Farmers told him that they'd never sell a tractor that cost that much. Anybody willling to pay $10,000 for a new 100 horse power tractor today? They wouldn't be able to build them fast enough. | ||

leo |

Is this the same for 1755's. I here alot of negative regarding the 1755, but, there are times when some swear by them. | ||

Chris Losey (Admin) |

I have heard some complaints about the 1755 too. My experience has been that with the lower horse power and no turbo, the 310 engine in the 1750/1755 was very reliable. I don't recall seeing any 1755's at salvage yards I have been at, while there always seems to be an 1855 for parts around somewhere. In my area, the 1755's and 1955's seemed to hold up good. It was the 1855 that gave the troubles. The main difference... the 1855 had a turbo with no oil cooler. I have a 1750 with the 310 and the injection pump turned up 10%. If I had to start raising money by selling the tractors, the 1750 would be one of the last ones to go. This tractor starts great, runs great, and gets quite a bit of use here on the farm. I would like to have a 1755 someday. Dsl had a nice one with FWA located for me in Quebec about 2 years ago. I hesitated too long, and now someone else owns it. In my post above, in the last paragraph I mis-typed 1885. It should be 1855. | ||

leo |

Chris, Were the later 1855's(74) any better built or updated than previous 1855's? Also, what could cause one to be extremely difficult to turn left or right? | ||

Chris Losey |

Definitely. By 1974 all 1855's had the same block with the integrated oil cooler as the 1955 had. The exact serial number was 244-324, which according to my serial number book was very late in 1973. There were some other modifications that were incorporated by that time as well, but they aren't as important as the 1955 engine. For the steering problem, it could be a couple of things. If it is hard steering both ways all of the time, I would say the flow divider/priority valve is sticking and not allowing enough oil to get to the the hyra motor. But if this is the case, then the brakes shouldn't have any power either. If you are talking about it steering hard one way and not the other, then it could be in the hydra motor, which could be 3-400 dollars to fix or replace. The other option is that the steering cylinder seals are leaking internally. This would allow the oil to push past the seals and dead head in the compartment where the rack engages the steering gear. There is a relief valve built into some of the rack cylinders to prevent this buildup of pressure. But if it sticks, there is no where for the oil to go. Later tractors had an oil line coming out of the top of the steering housing cap that would T into the cooler line to return to the reservoir. If it has this line coming out of the top (it's only about 1/4") then the steering cylinder probably isn't the problem. Resealing the steering cylinder/rack is pretty easy and should only cost the price of a few o-rings. Check the brakes for good pressure feedback on the pedals. If they are working properly, I would lean towords there being something wrong with the hydra motor. | ||

leo |

Thanks Chris, Have not gotten it home yet, but looking forward to it. At the auction, it seemed to run really nice, only has 3100 hours, and was purchased new. I'm new to anything above the 1655, but really like this 1855. It is a diesel utility model. I'm sure I will have more questions in the coming days. | ||

leo |

Chris, The brakes do not seem to have power. Does this point more to flow divider/priority valve sticking? If this is the case, what are the best remedies? | ||

Chris Losey |

The first thing I would do is tear apart the priority valve and clean it up. There is probably a piece crud that is on the valve spool that is keeping it from moving properly. It's been awile since I have done this, so I am going to have to check my service manual to know for sure which cap you have to remove off the valve body to get to the priority valve. I should have more info for you by tonight. | ||

Chris Losey |

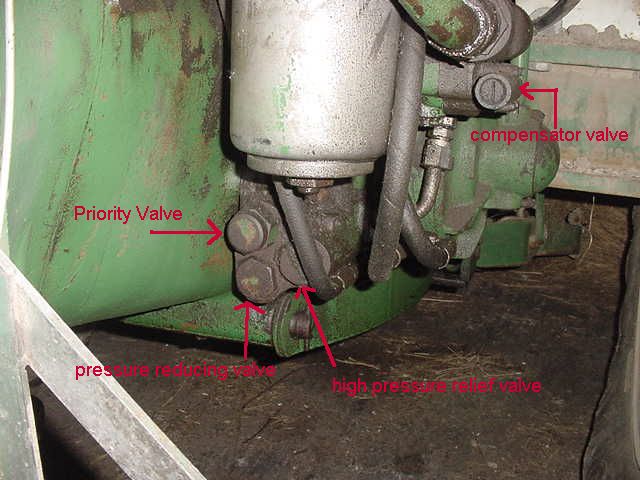

Before we get tearing into stuff too quick, lets do some more diagnostic work. Are you getting pressure at the remotes and 3 point hitch? Hook a heavy implement to the tractor and try to lift it. If you aren't getting good pressure at the remotes or 3 point then something else would be at fault. It then could be the unloader valve, the compensator valve, the high pressure relief valve, or the relief valve on the 3 point lift cylinder could have broken off. The worst thing would be a broken hydraulic pump. If you have good hydraulic pressure at the remotes and 3 point, then try the priority valve. I have scanned 2 pages from the service manual that cover this valve and added them to the photo gallery in the service album. They give a good explaination of how to remove the valve. It doesn't take much forgein material to make the spool stick. Here is a picture of the valves on my 2255. They should be the same on your 1855.  | ||

leo |

Chris, I did get the steering free. Apparently, the tractor had not been moved in 3 years. A little wd-40 cleared it up real good. The tractor seems to be ok, though I know virtually nothing about the 1855. Is the gear pattern the same as the 1655? Also the over/under, is it the same as 1655? I dont seem to have any brake on the left side. It seems powerless. I will try the hydraulics tomorrow. | ||

Chris Losey |

The shift pattern is different for the 1855. This is from memory, but it should be like this. 2...R1 |-|-| 1...4 5...R2 |-|-| 3...6 The over/under is almost the same bewteen the 2 models. The big difference is the input shafts are different. The internal working parts are almost completely interchangeable. It could be that since the tractor has been sitting for 3 years that things are siezed up some in the brake housing. You might try using it for a while to see if it will free up, but that could be dangerous. There also could be air in the brake psiton. There is a bleeder screw that you can open up while holding the brake pedal to remove any air. This would be an easy way to see if you are getting pressure at that brake too. If you need to open the brake housing to see if anything is siezed, it is pretty straight forward. Just remove the hydraulic brake line, unhook the parking brake lever and take the bolts out around the outer edge of the brake cover. Then just pull the cover off. You'll be able to to see if stuff is rusted up in there, or if the brake discs are worn out. | ||

leo |

Chris, You are so much help, thanks. I ran tractor a little this evening and it appeared that with the over/under, the middle position seemed to be fastest gear. Because the throttle and hydraul shift are somewhat frozen together, i can seem to tell alot of difference between upper drive.top position, and lower drive..bottom position. With my 1655, it is botton..under, mid..direct, top..overdrive. I can tell the difference with the middle position. | ||

Chris Losey |

The over/under should work exactly like the 1655, with the lowest position under drive, middle is direct drive and the top position is over drive. It could be the linkage just isn't moving far enough if it is rusted to the throttle shaft. My 2255 has a misplaced hose or something in the dash that can keep it from going far enough to go into over drive. A little wiggling and it will move and away it goes. I don't know how cold it is where you are, but in real cold weather while the over/under is cold, you can get enough viscous drag from the oil to make the higher ranges act like they are engaged under no load situations like driving around the drive way. My White American will actually slow down going from under drive to direct drive because the over drive clutch pack is dragging. It's nothing to be concerned about, it's just from cold thick oil. Once the oil warms up, everything works fine. Try shifting it in road gear and see how it does. There's enough load to overcome any viscous drag and there is a more noticable difference between the speed ranges. If there is something wrong with the over/under, you're pretty much looking at pulling the motor and tearing into the unit to fix the problem. About the only thing you can do from the outside is check pressures and remove the relief valve. You can see if the lever is moving properly by shifting it with the tractor off and standing by the right side. This is my 1655 but the 1855 works the same way. The lever with the red arrow pointing at it and with the yellow line on it is what move the spool in the over/under unit.  When the top of the lever is closest to the engine, it is in under drive. As you shift you should be able to see it jump to the next position as the detent ball inside the cover 'locks' the spool into direct. The same will happen going into over drive. If you feel that something is binding in the linkage, unhook the rod from the lever and try moving the lever by hand. (Of course with the tractor parked and in neutral). You can also CAREFULLY do this with the engine running and you you should be able the tell a difference in the speed of the coupler chain with each shift. Just don't run yourself over or get caught in anything. | ||

leo |

Many thanks to you. It amazes me how good tractors go to bad just sitting. I've been reading about the rod bolts in these 310 engines. Would it be a good idea to replace mine? Listening to some of the guy's, this caused lot's of engines to fail. | ||

Chris Losey |

It certainly couldn't hurt. $140 in rod bolts is far cheaper than a blown up engine. It is amazing how fast things go down hill when a tractor just sits around. I think this is one of the major reasons that the brakes don't always work consistently on some Olivers. My 1750's brakes work much better after a day of picking up round bales in the field. |